If you’re interested in using wood as a major part of your crafts and DIY projects, investing in a laser cutting machine might be a good idea. However, with so many varieties available in the market, choosing a laser cutting machine that’s suitable for your needs can be a difficult task.

In this post, we’ll go over the benefits of this woodworking tool, explore the usage of laser cut wood, and shine a light on the factors that you need to consider when selecting a laser cutting machine for your crafts.

Advantages of Using Laser Cutting Machines for Wood Crafts

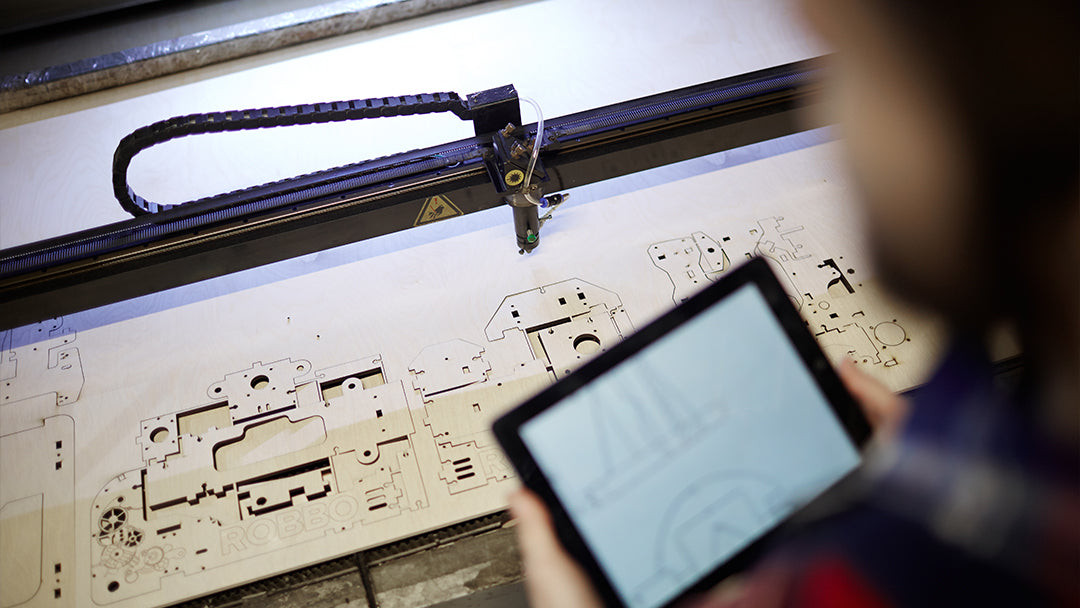

A laser cutting machine uses a high-power focused laser beam to burn or vaporize certain materials like wood to cut through it. Compared to more traditional wood cutters, laser cutting machines come with benefits such as the following:

- Precision- Laser cutting machines offer a high-degree of precision which allows for the creation of complex designs that would otherwise be very difficult to achieve by hand and other traditional tools. This also means that you’ll require fewer reworks, saving you time and material.

- Consistency- Since the laser beam that cuts the wood is controlled by a computer program, cuts are uniform and the resulting pieces look identical.

- Speed- Laser cutting machines are incredibly fast tools that can reach a top cutting speed of 600m/s. This will save you a lot of time, enabling you to finish your projects faster.

- Flexibility- Unlike with traditional wood cutters where you need different types of tools to cut a variety of shapes, you can use the same setup with your laser cutting machine with the same types of wood and thickness.

- Versatility- Laser cutting machines are more than just a tool for cutting wood. They can also be used to engrave on wood, even on pieces that have an uneven surface. You can also use it to work on other types of materials like metals, acrylic sheets, paper, and some types of fabric.

- WasteReduction - Since laser cutters are incredibly accurate, there is minimal waste due to error.

- Contactless Cutting- With laser cutting, only the beam comes into contact with the wood. This means that you won’t have to worry as much about worn down and blunt blades, saving you money in terms of maintenance and repair.

- Reduced Need for Finishing- Since the laser beam can make smooth, clean, and precise cuts, you won’t need to spend so much time and effort with post-cut finishing.

What Are Some Common Uses of Laser Cut Wood?

Now that you have a better understanding of the benefits of using laser cutting machines for woodworking, let’s delve into some popular uses of laser cut wood in crafts and DIY projects.

- Wooden Signs- You can create wooden signs that you can hang at your front door or as part of your home decor. You can also personalize your kids’ rooms with their names beautifully cut out from wood.

- Keychains- Make wooden keychains that you can use as party giveaways from small pieces of wood. You can even paint them or attach some beads.

- Jewelry- Gift your friends beautiful pieces of wooden jewelry like earrings and rings. You can even engrave it with their names to make them even more special.

- Christmas Ornaments- Make 3D or flat Christmas ornaments using light pieces of wood. From angels, stars, pine cones, and candy canes, there are so many designs that you can try.

- Wooden Toys- Surprise your kids with a wooden model of their favorite character or automobile.

- Organizers- Level up your home organization with DIY drawers and cabinets. You can even engrave or cut out intricate patterns to give them that wow factor.

How to Select A Wood Laser Cutting Machine for Crafts?

Next, we’ll go through the different factors you need to consider in finding the perfect wood laser cutting machine for your crafts and DIY projects.

Price

Depending on your budget, there are three types of lasers that you can choose from.

- Fiber Lasers- These are perfect for heavy-duty jobs and mostly used in industrial environments. As such, they require a very high investment.

- CO2 Lasers- This is a great choice if you’re planning to use your laser cutting machine to start a small business. Since these laser cutting machines usually have 45W of power and more, they have a faster cutting speed and can handle thicker and harder types of wood compared to diode lasers. Expect to spend anywhere from $2500 to $7000.

- Diode Lasers- Affordable and accessible, it’s the ideal pick for wood crafts and DIY projects. You can get them for under $1000, though there are good ones in the $600-700 price range already. Just make sure to buy a blue laser diode instead of an IR laser module since this one is for metal and glass engraving, not wood cutting.

Wood Type and Thickness

You’ll also need to consider the type of wood and thickness that you’ll be working on for your projects. Some types of wood are denser and harder to cut, requiring higher laser power and multiple passes to achieve good results.

For example, softer hardwoods like basswood, alder, and poplar can be cut by lasers with under 40W power. However, for hardwoods like birch, maple, bubinga, and walnut and thicker sheets of soft hardwoods, you’ll need more power.

To get a better understanding of the most common types of woods used in laser cutting and how much power they require depending on thickness, please check out our Guide to Choosing Woods for Laser Cutting.

Machine Bed Size

The machine bed refers to the laser cutting machine’s work area. Consider the types of projects that you’re planning to work on and get a laser cutting machine with a bed size that’s equivalent to their dimensions.

Some laser cutters also have features that expand their working areas.

- Passthrough Doors- Ideal signs and other projects where you’ll be using longer pieces of wood, these machines have a removable side where you can feed longer sheets of wood.

- Extension Kits- Laser cutters that don’t have an enclosure sometimes come with extension kits that increase their work area.

- Removable Floor- You can engrave materials that are larger than your laser cutting machine if it has a removable floor.

Enclosure and Fume Extractor

Laser cutting wood produces fumes and gas. So, it’s best to choose a laser cutting machine with an enclosure or an option to add one. This allows you to use fume extractors that direct the fumes to a vent or window. When using extension kits, there should be a matching larger enclosure. If you don’t have an enclosure, you’ll need a very effective ventilation system.

Air Assist

Hardwoods like cherry and oak that require higher laser power are prone to burning that leave undesirable scorch marks. In cases like this, an air assist feature can reduce the chances of burning by blowing a stream of air where the laser meets the wood.

Add-On Attachments and Features

Features like a pause button, camera, red dot pointers, autofocus, and Wi-Fi connectivity make laser cutting wood easier and more efficient. A rotary attachment is also handy when engraving on cylindrical wood pieces.

On the other hand, there are safety features like a laser-filtering lid, fire detection and extinguishing system, and emergency buttons that can help guarantee your safety especially when you’re working with potential fire hazards like wood. The best options are Class 1 safe laser cutting machines which meet the highest laser safety standards from the International Electrotechnical Commission (IEC).

Cooling System

CO2 laser cutters often come with a water cooling system because they quickly get hot. If you want to use your CO2 laser cutting machine for longer periods of time, it’s best if it supports the addition of radiator water chillers and external cooling systems.

Compatibility

Some laser cutting machines are compatible with Lightburn, a popular laser software for home crafters while others need proprietary software. Make sure that your chosen laser cutter is compatible with your favorite software or has a software that’s easy to use. It should also be able to work with the platform or operating system that you’re using.

Final Words

There are so many possibilities when it comes to crafts and DIY projects with laser cut wood. You can go as far as your imagination will take you. Once you become adept at using your laser cutting machine, you can even use it to start a small business selling handmade wooden trinkets or home decorations.Wooden crafts exude warmth and have a timeless look that make them a classic favorite. Of course, these all begin with the right laser cutting machine that meets all your needs.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.