3D wooden puzzles have become a popular pastime for both children and adults because of the fun and challenge that they offer. While they are indeed aesthetically pleasing and provide a one-of-a-kind assembly experience, have you ever wondered how they are made? In this post, we'll share with you the step-by-step process of making 3D wooden puzzles.

Project Establishment

Before anything else, the team brainstormed about the concept and theme of the puzzle. They also decide on the size, difficulty, and how many pieces the puzzle should have. They also tackle what kind of features it should have. Will it have different lighting modes? Should it have sound effects or play music? Will there be mechanical parts that make it move? What is its purpose and what makes it special?

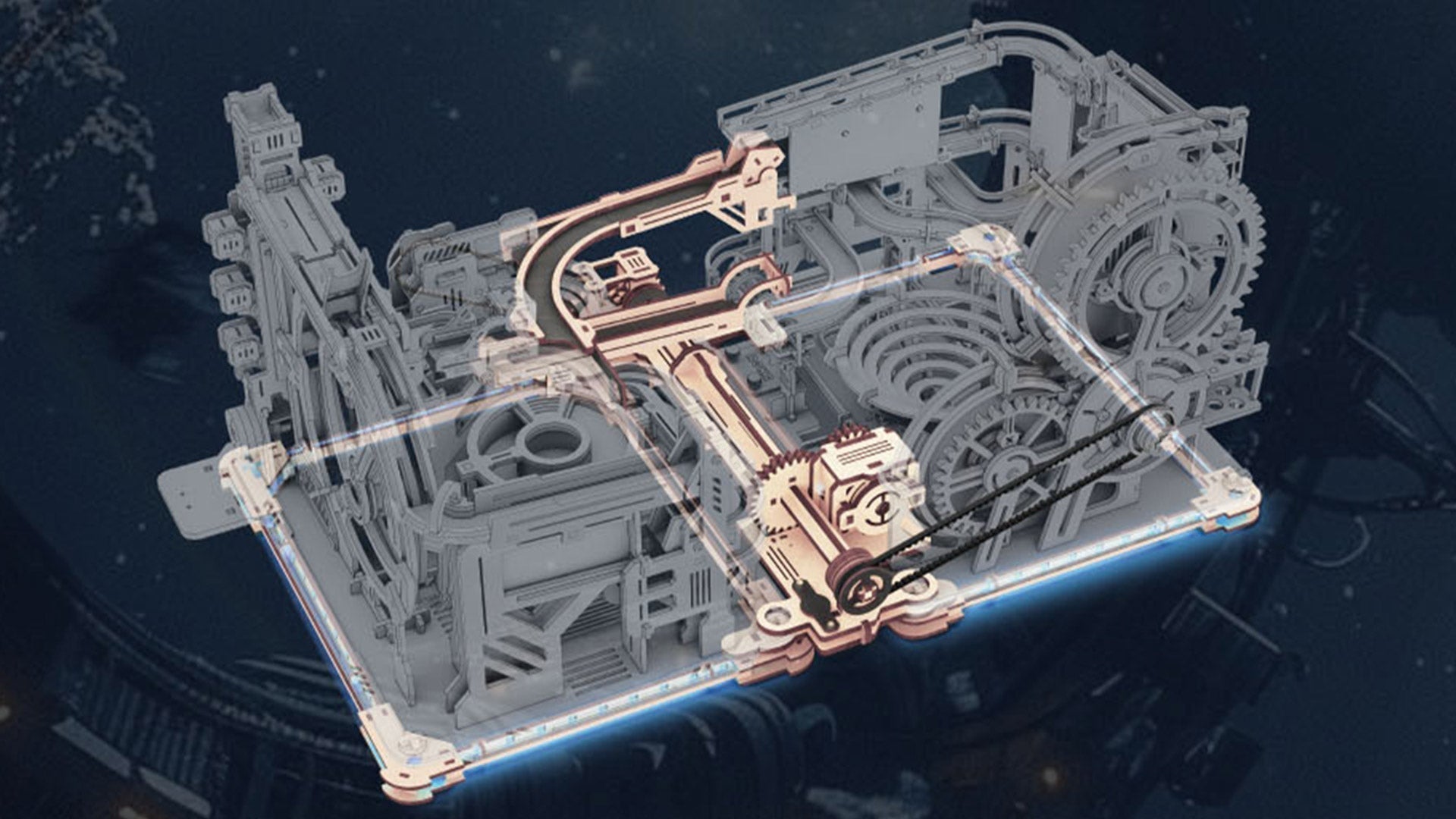

ROKR Marble Night City Marble Run Line drawing

Design

The designer then creates detailed sketches based on the theme, concept, and features that have been decided upon. Next, the designer uses computer-aided design (CAD) software to outline each puzzle piece and their connections. This software allows the designer to enter specific measurements and calculations and even view the model from different angles.

The designer makes sure that each puzzle piece is unique in terms of size and shape to make them easily distinguishable from the other puzzle pieces. The stability of the completed puzzle and its aesthetics are also taken into account.

Once the 3D model is done, the designer creates a set of instructions that can include images, diagrams, and written instructions that will guide the users at each stage of assembly.

Trial Production and Test

Next, the design is sent to the production team so they can create a trial product to test. Do the parts fit perfectly? Does the design fit the theme and is it visually appealing? Are the added features working properly? Is the completed puzzle stable?

If the trial product passes inspection, then it is ready to be manufactured. Otherwise, it will be returned to the designer for corrections.

Making the 3D Wooden Puzzle

Choosing the Wood

Once the design is ready for production, the type of wood that best suits the puzzle is chosen. High-quality 3D wooden puzzles are typically made of hardwoods such as maple, birch, mahogany, or oak. Aside from being strong and durable, these hardwoods are known for their appealing grain patterns. The chosen wood is kiln-dried to remove moisture and prevent it from warping over time.

Cutting the Pieces

Once the design and wood are ready, it’s time to start cutting. There are three ways to cut the wood:

1. Laser Cutting

The most common method of cutting wooden puzzle pieces is by using a laser cutter. The design is programmed into the laser cutter. Then, a high-powered laser beam will burn the wood, precisely cutting it into the shapes and sizes indicated in the design. Aside from having minimal waste, laser cutting is great for cutting intricate shapes and details with clean edges.

2. Scroll Saw Cutting

A scroll saw can also be used to cut the puzzle pieces. This stationary machine sports a fine blade with a rapid up-and-down movement for cutting. While scroll saw cutting offers more in terms of control than laser cutter, it takes considerably more time.

3. CNC Routing

For complex designs, the best method of cutting is CNC routing. It’s a computer-controlled machine so it is able to carve out the puzzle pieces with utmost precision and accuracy.

Sanding the Wooden Sheet

To make sure that the wooden puzzle pieces fit perfectly, the wooden sheets are sanded down in increasing fineness. Manufacturers use either sandpaper, sand blocks, or power sanders to remove imperfections and rough edges.

Depending on the desired look, the wooden pieces can be stained, painted, or simply treated for protection. Several coats of oil, wax, or lacquer are applied to create a smooth and even finish.

Packaging

Quality control goes over the batches of manufactured products to make sure that there are no issues or defects. Once they pass inspection, the wooden puzzle sheets are packed in individual boxes along with the assembly instructions, glue, paint, and other necessary tools required to assemble them. Once the boxes have been sealed, they’re now ready for shipping.

Conclusion

It takes a lot of patience, creativity, craftsmanship, and attention to detail to create 3D wooden puzzles. Each step, from conceptualization to packaging, must be successfully completed to create a high-quality puzzle that consumers can enjoy. Now that you know the process of 3D wooden puzzle-making, you’ll be able to fully appreciate just how special they are even before assembling them.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.