Have you ever noticed the charm of wooden puzzles? From the very past till now, people have been entertained by them as they bring together the two elements of art and entertainment. In addition to being entertaining, wooden puzzles are trending once again as the worldwide market for puzzles is expected to hit 3.02 billion dollars by the year 2025 with an annual growth rate of 3.45% up until 2029.

The creation of these detailed puzzles requires a particular form of cutting that offers accuracy while also providing durability. From crafting by hand to state-of-the-art technology, every procedure has its own distinctive contribution in shaping the puzzles.

In this guide, you will learn about the major processes involved in cutting wooden puzzles and the artistry involved in changing the raw materials into captivating pieces of art.

Traditional Scroll Saw Cutting

For many years, the technique of crafting wooden puzzles has relied upon the scroll saw cutting method. Carving complicated designs is achievable through a scroll saw, a small electric or pedal-operated saw that cuts delicate curves into wood, metal, and various materials. Its intricate blades enable the creation of complex pieces by executing detailed and precise cuts, making it ideal for puzzle creation.

Source: freepik

The Scroll Saw and Its Operation

A scroll saw functions by rapidly driving its blade up and down which allows the cutting of very complex and detailed patterns and shapes. Usually an artisan would begin with selecting a piece of wood, often with some sort of high-quality plywood because it is reliably durable and has a smooth finish.

The desired puzzle template is either drawn or glued on the wood’s surface. While the artisan positions the wood on the saw, the artisan uses careful technique to ensure they follow the design, achieving precise cuts that create the individual puzzle pieces.

Advantages of Scroll Saw Cutting

One of the primary advantages of crafting puzzles with a scroll saw is the ‘artistic’ freedom they can exercise. Craftspeople are able to create unique, handcrafted patterns that cannot be duplicated with industrial production systems. Another advantage is that the blade can be put in and taken out of a hole, allowing complex designs to be created.

Challenges and Considerations

Even though it has its advantages, traditional scroll saw cutting is very time intensive and requires a lot of skill. Traditional cutting is very intricate. A steady hand and expertise are needed to ensure everything is done perfectly, and tending to the details is exceptionally time-consuming. Also, the blades are easily breakable which makes precision blades for exotic woods or complex designs particularly difficult to work with.

People continue to appreciate traditional scroll saw cutting when making wooden puzzles because of its artistic value. It allows craft workers to make puzzles that combine artistry with handcrafted techniques. Today's manufacturing methods speed up production yet scroll saws keep their importance because they help artists make unique detailed designs with their professionalism.

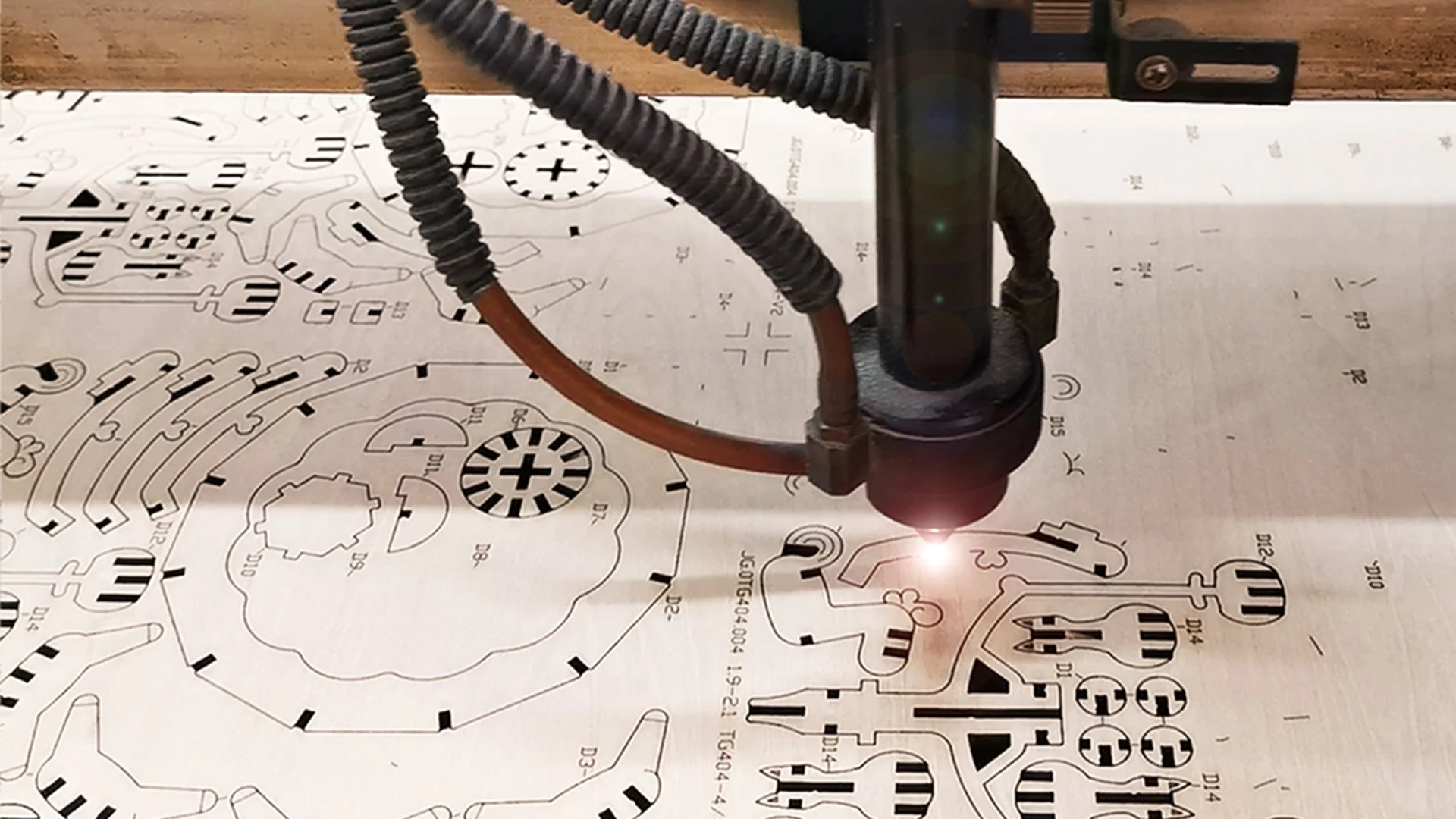

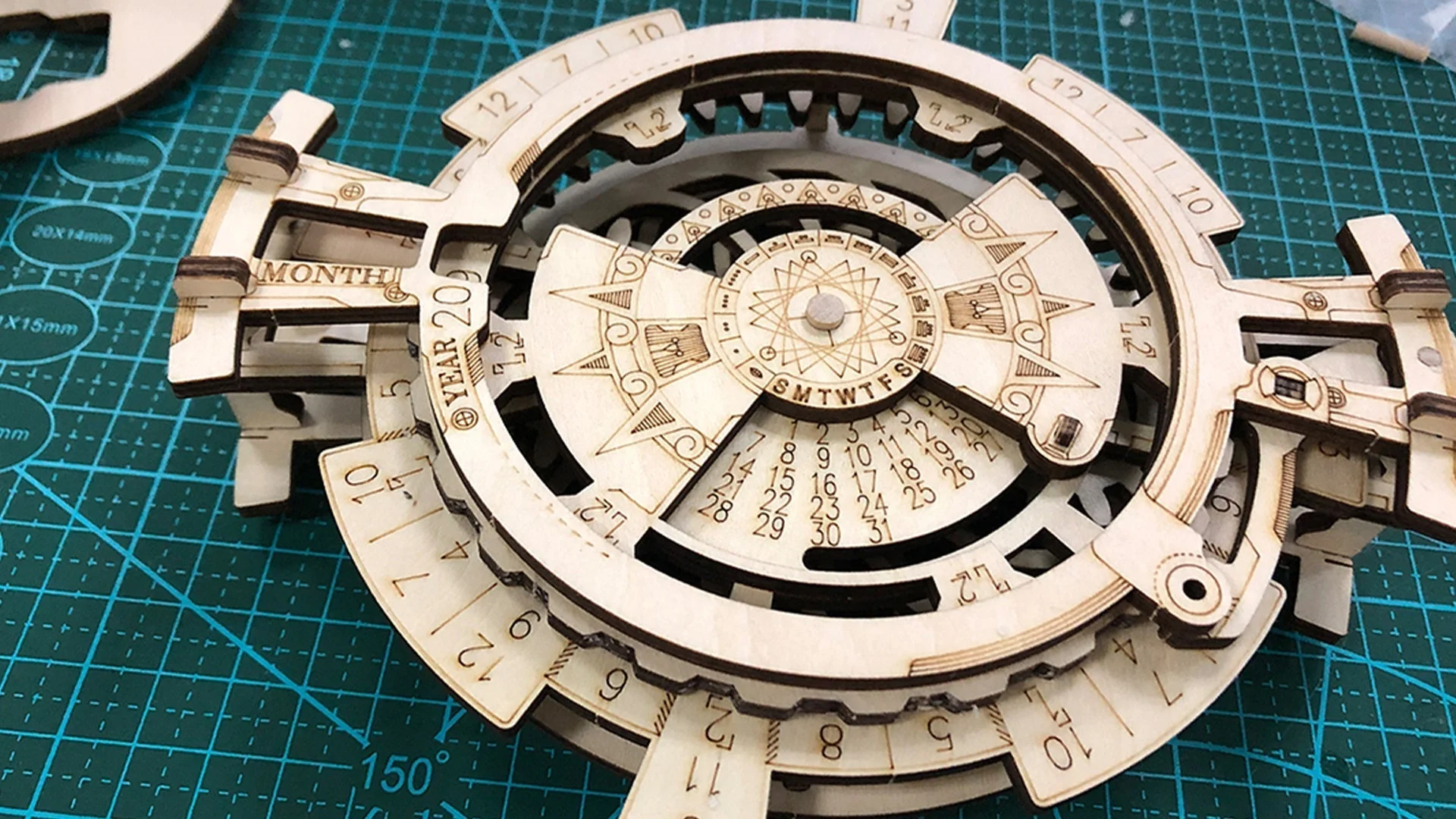

Laser Cutting Technology

Advances in laser cutting technology have improved the design and manufacture of wooden puzzles unlike ever before. Looking more closely at how they are made, considering a laser cutting machine, a focused laser is sent to wooden sheets and cuts them into pieces.

Shapper edges and detailed patterns are easier to produce, increasing the value of each sheet cut. The precision of laser cutting guarantees that each puzzle piece surpasses the standard of seamless joining, further improving the ease of putting the puzzle together.

Advantages of Laser Cutting in Puzzle Manufacturing

The advantages of using lasers to cut materials include speed and accuracy. Because of the automation, there is less manual work which increases production while maintaining quality standards. This is certainly helpful when products are manufactured in bulk, as uniformity and speed are crucial. Also, laser cutting allows for the creation of customized designs, which gives manufacturers the ability to meet the needs of many customers.

Considerations and Post-Processing Requirements

While laser cutting has many advantages, the method also has drawbacks such as the possible charring of wood on the borders due to excessive heat. Charring can require significant additional cleanup work, including but not limited to sanding and polishing, in order to meet standards of visual appeal. To meet ideal thresholds for aesthetic quality, manufacturers need to incorporate this step into their processes.

Laser cutting technology has enhanced the artistry of wooden puzzles by melding traditional craftsmanship with high-tech accuracy. Knowing the advantages as well as the difficulties of this approach, one can admire the care that is taken in creating these captivating puzzles.

Die-Cutting for Mass Production

In crafting wooden puzzles on a commercial scale, the die-cutting method is very efficient because uniform pieces of wood are patterned into intricate shapes with the aid of metallic templates or dies. The metal dies guarantee that uniform pieces of wood will be cut into intricate shapes which makes this method preferred in mass production.

Process of Die-Cutting

The first step of die cutting involves making a die which is a flat board, mostly plywood, where steel blades are put to create a puzzle pattern. A hydraulic press is used to cut the puzzle pieces out of a wooden sheet. The press applies a lot of force to engrave the design on the sheet which cuts the wooden puzzle pieces. This allows us to make a large number of similar puzzles quickly.

Advantages of Die-Cutting

One of the highlighted benefits of die-cutting is its speed in high-volume production. Manufacturing cost is less for producers because they can manufacture large quantities of puzzles within a quick timeframe. Also, the precision that die-cutting enables guarantees that every part of a puzzle is identical in shape and size, increasing the ease of assembly for the user.

Limitations of Die-Cutting

Even though die-cutting is efficient, it's not ideal for greater customization and more elaborate designs. The die's inflexibility makes it difficult to produce complicated patterns, forming puzzles with detailed or intricate piece shapes is quite challenging. Also, the creation of the new die's initial setup can be costly and time intensive, which does not suit small-scale or tailor-made production cycles.

Supporting die-cutting technology aids in balancing both quality and productivity when mass-manufacturing wooden puzzles. While it is advantageous for making large quantities of standardized puzzles, it is not ideal for more personalized designs that require advanced detailing.

Source: freepik

CNC (Computer Numerical Control) Routing

The introduction of Computer Numerical Control (CNC) routing provided precision automation in the wooden puzzle manufacturing industry. Nowadays, CNC Routers are sophisticated machines that automate the carving of wood puzzles and allow for the intricacy and superior craftsmanship of master puzzles.

Advantages of CNC Routing in Puzzle Production

The main advantage of CNC routing is its ability to make exact duplicate cuts that will solve together as one perfect puzzle. CNC routing technology makes it easy to build complex shapes that a human cannot produce so manufacturers use it to create high-quality puzzles. The continuous operating capability of CNC routers helps speed up production and lower the time needed to create each puzzle.

Considerations When Using CNC Routers

You can take advantage of CNC router benefits yet you still need to think through key points. A CNC machine setup costs heavily in the beginning and this requirement poses an entry challenge to small producers. Special training becomes necessary to keep CNC machines working properly and setting up programs. CNC routing helps wood puzzle companies succeed through its exact tooling power and automated production while letting them create elaborate designs.

The mixing of modern technology with traditional puzzle making allows CNC routers to craft precise and high-end wooden puzzles in an optimized manner.

Source: freepik

Wood Selection and Preparation

The choice and treatment of wood determine your ability to make top-quality wooden puzzles. Manufacturers select birch plywood hardwoods and MDF because these materials remain strong while producing a polished surface. The 5-ply birch plywood tops other choices as its strength and dimensional stability keep puzzle pieces aligned throughout construction.

The wood passes through sanding and polishing steps to create accurate results that make puzzle segments connect perfectly. The surface preparation helps cut pieces move easily through each other without obstacles. The manufacturer adds printed artwork directly to wood before it undergoes cutting to enrich the puzzle design.

Finishing and Quality Control

Producing superb wooden puzzles depends on completing the production process correctly. The team finishes each cut puzzle piece by sanding it to create perfect matching connections. The sanding process makes puzzle pieces more comfortable to handle and helps users complete the puzzle more easily.

Manufacturers apply edge-sealing varnishing and painting methods to make products more durable and pleasing to look at. These finishing methods shield wood against both water harm and rubbing while enhancing its appearance. The quality team completes rigorous checks to find splinters and bad cut edges on every puzzle to guarantee professional quality production.

Wrapping Up

Wooden puzzle creation brings together old-fashioned skill with precise engineering tools. Traditional scroll saws and modern CNC tools along with lasers provide specific advantages for creating wooden puzzles. The final look of the piece depends on good wood choices plus proper work and finish techniques. All these steps produce entertaining puzzles that interest people everywhere.

Why put off stimulating creativity and challenging your mind? Take a look at Robotime's amazing assortment of wooden puzzles and unlock boundless potential. From detailed patterns to do-it-yourself miniatures of houses, books, and other one-of-a-kind gifts, everyone is catered to. Get started on your puzzle-solving adventure with new arrivals of Robotime today!

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.