Throughout the years of innovation and improvement in various industries and companies, several processes have needed the assistance and involvement of cutting technology, such as laser and flame-cutting methods. The revolution started for efficiency, convenience, and mass production, which benefited the growth of both commercial and industrial sectors. Flame and Laser cutting have provided their best performances among different applications with accuracy and faster operations. To better understand the key differences and purposes of both cutting methods, continue reading below to analyze which suits your cutting procedure.

What Is Flame Cutting?

Flame cutting uses mixed oxygen and acetylene to work its general purpose of cutting materials, such as metals. It has a torch that works directly in the cutting process, and each cylinder is for oxygen and acetylene. Various industries and manufacturing companies have widely used this cutting procedure because of its ability to slice thicker metals and materials. It is also considered a cost-effective cutting method.

In terms of the flame-cutting process, once the gas hits the torch through the hoses, it will start a spark that can melt down a metal or any thick material until they are cut down on its specific sizes and dimensions. Also, the maximum temperature in flame cutting is 3,500°C.

What Is Laser Cutting?

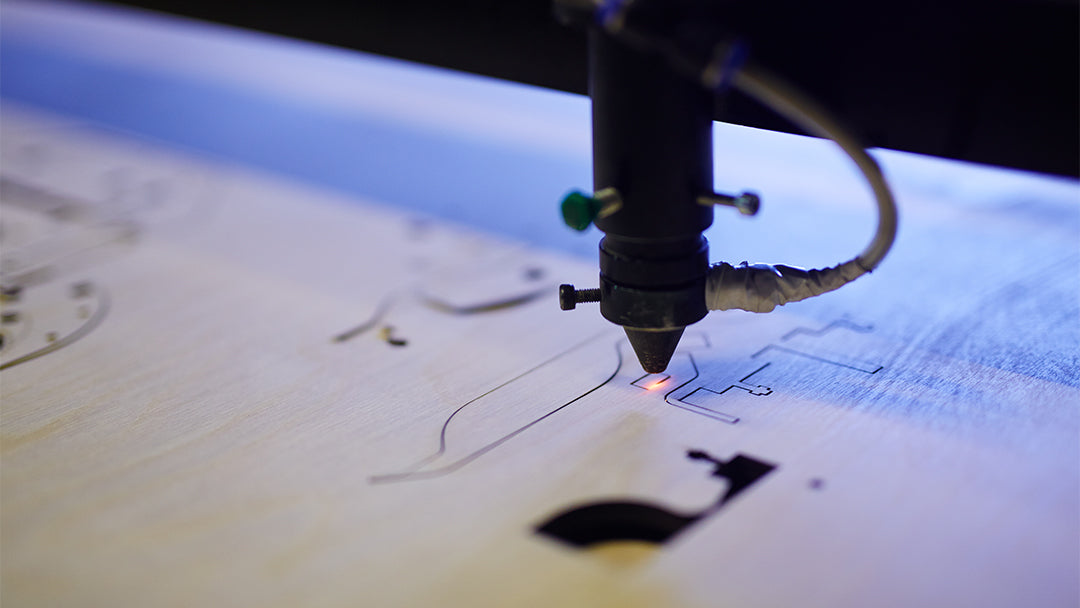

Laser cutting helps cut metals, wood, and acrylics using laser light, beams, and lenses. It is one of the cutting methods used in different high-end and powerful operations and productions because of its precise and accurate results. Aside from that, manufacturers are also taking advantage of its ability to make complex designs out of cutting.

The only downside of laser cutters is that they come in a costly price range depending on the complexity of the machine's design, which starts from basics to intricate engravings. The laser cutting process starts with a concentrated laser beam transferred through a controlled and guided lens to cut a specific part of the materials. It can be controlled using a computer and a cooling system during its operations for more efficiency and accuracy.

For more information, visit What Is Laser Cutting And What to Use It For?

What Are the Differences Between Laser and Flame Cutting?

It must have been confusing to decide between a laser and flame cutting. To help you compare the two, here are critical differences regarding specific factors. Check them out to ensure you have an in-depth idea of the details you need to consider.

Versatility

Regarding versatility, the best option in the line is laser cutting. Aside from the automatic and computerized controlling process in laser cutting, it can also work in various metal and non-metal materials, making it a safer option. Since flame cutting is only advisable for metals, it offers a smaller production scale and operational performance than laser cutting.

Applicable Materials

Laser cutting works flexibly in various materials, both in metals and nonmetals. It is a perfect choice if you are after the flexibility in selecting cutting materials for your next project. Compared to laser cutting, flame cutting only applies to thick materials like metals, which means its general cutting purpose is limited. Additionally, you can use laser cutting’s ability to perform in complex designs and patterns.

Common Application Areas

The two cutting methods are used in different industries depending on their specializations and applications. For flame cutting, most companies that take advantage of its purpose are processing high-end steels with thickness and durability. Most industries in shipyards, plantation engineering, mechanical operations, and steel construction and production use flame-cutting devices for the drilling and cutting system of pipes, metals, and thick walls.

On the other hand, laser-cutting devices are seen primarily in companies that require complex patterns or intricate designs on their products. In the automotive industry, a laser cutting device is essential for cutting the metal parts of vehicles. Laser cutting is also vital for cutting wood and metals into special shapes and designs in the furniture industry. It is also found in the kitchenware industry for engraving steels, glasses, ceramics, and more materials and utensils you can mostly see in the kitchen.

Cut Quality

The presence of the laser beam in laser cutting gives a better outcome to operations with smoother surface finishes and edges. In contrast, the melted materials that solidified after the cutting process in flame cutting provide a rough surface finish. It is why most companies choose laser cutting, especially for projects that require smooth finishes, like acrylics.

Cutting Accuracy

In terms of cutting accuracy, laser cutting has the advantage compared to flame cutting. The laser beam included in the laser cutting process offers an accuracy of 0.0127 mm dimension, which is perfect for complex designs and patterns. Also, because of this cutting accuracy, most manufacturing companies making products out of tight tolerances consider laser cutting compared to flame cutting.

Nuisance during the Cutting Process

Based on the description of the flame cutting regarding the gas mixture used for it to work, it only highlighted that the cutting procedure with this method would be noisy and risky. This is because the process requires open flame by using flammable gasses. If you want a relatively safer and quieter option during your cutting procedures, the right one is laser cutting. It only uses an ample amount of gas during operation.

Maintenance

During operations, quality control management and detailed maintenance are also in both cutting methods. But the laser cutting machine only requires a little of it since the only parts that need proper cleaning and maintenance are the laser head. On the contrary, flame-cutting devices need regular inspection and maintenance because of their heavier moving parts compared to laser cutting. If you are after less effort in inspecting, laser cutting is your best option.

Summary

Both laser and flame cutting are in demand in various industries and manufacturing companies, depending on how their purposes are utilized and used. Most projects and applications that require efficiency and effective cutting operations need the presence of their specializations. As described in this article, laser and flame cutting differ in their applicable materials, maintenance, common application areas, cutting quality and accuracy, and more. In determining which of them to use on your next project, it is best to analyze the details and see which description suits the application. If you plan to level up your cutting operations with any of these two, do not hesitate to review the article for an in-depth understanding of the factors you need to consider and their key differences and specializations.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.